A project to 3D-print bulky components in space rather than bring them up there has collected a $73.7 million contract from NASA to demonstrate the technique in space. Archinaut, a mission now several years in development from Made In Space, could launch as soon as 2022.

The problem at hand is this: If you want a spacecraft to have solar arrays 60 feet long, you need to bring 60 feet of structure for those arrays to attach to — they can’t just flap around like ribbons. But where do you stash a 60-foot pole, or two 30-foot ones, or even 10 six-foot ones when you only have a few cubic feet of space to put them in? It gets real complicated real fast to take items with even a single large dimension into space.

Archinaut’s solution is simple. Why not just take the material for that long component into space and print it out on the spot? There’s no more compact way to keep the material than as a brick of solid matter.

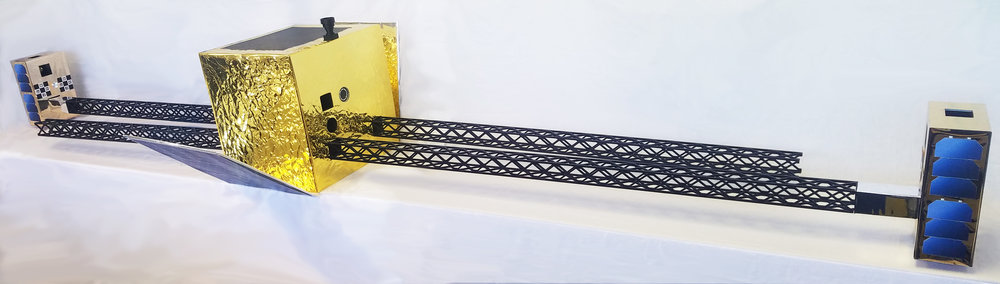

Naturally this extends (so to speak) to more than simply rods and poles — sheets of large materials for things like light sails, complex interlocking structures on which other components could be mounted… there are plenty of things too big to take into space in one piece, but which could be made of smaller ones if necessary. Here’s one made for attaching instruments at a large fixed distance from a central craft:

Made in Space already has contracts in place with NASA, and has demonstrated 3D printing of parts aboard the International Space Station. It has also shown that it can print stuff in an artificial vacuum more or less equivalent to a space environment.

Made in Space already has contracts in place with NASA, and has demonstrated 3D printing of parts aboard the International Space Station. It has also shown that it can print stuff in an artificial vacuum more or less equivalent to a space environment.

The demonstrator mission, Archinaut One, would launch aboard a Rocket Lab Electron launch vehicle no earlier than 2022, and after achieving a stable orbit, begin extruding a pair of beams that will eventually extend out 32 feet. Attached to these beams will be flexible solar arrays that unfurl at the same rate, attached to the rigid structures of the beams. When they’re finished, a robotic arm will lock them in place and do other housekeeping.

You can see it all happen in this unfortunately not particularly exciting video:

Once finished, this pair of 32-foot solar arrays would theoretically generate some five times the power that a spacecraft that size would normally pull in. Because spacecraft are almost without exception power-starved systems, having more watts to use or store for the orbital equivalent of a rainy day would certainly be welcome.

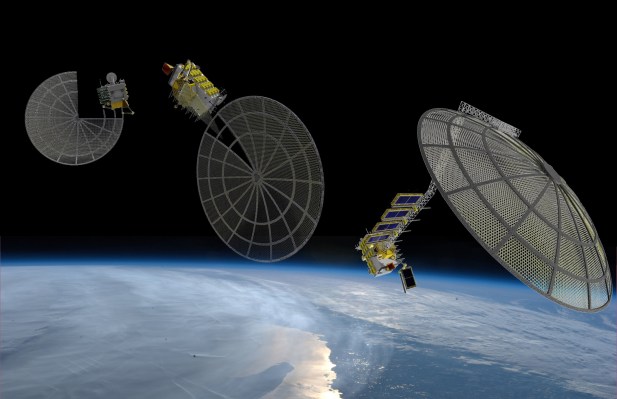

In another print, the robot arm could rearrange parts, snap on connectors and perform other tasks to create more complex structures like the ones in the concept art up top. That’s still well in the future, however — the current demonstrator mission will focus on the beam-and-array thing, though the team will certainly learn a lot about how to accomplish other builds in the process.

Naturally in-space manufacturing is a big concern for a country that plans to establish a permanent presence on and around the Moon. It’s a lot easier to make something there than make a quarter-million-mile delivery. You can keep up with Archinaut and Made In Space’s other projects along the space-printing line at the company’s blog.